If you make or assemble any products – say handmade candles, custom jewelry, or DTC furniture – you’ve got “stuff” in three stages: raw materials (unused parts), products in production (WIP), and finished goods (ready to sell). Work-in-process inventory is the middle stage. It covers any items that have begun manufacturing but aren’t finished yet. In other words, WIP includes all the labor and materials invested so far in a product that’s still under construction.

For example, if you sell baking mixes, flour and baking powder are raw materials; the mix just after combining ingredients is WIP; and the boxed, labeled mix ready on the shelf is a finished good. In accounting terms, WIP sits between raw materials and finished goods on your books. Raw materials are unused parts; WIP is anything currently being worked on; finished goods are complete products ready to ship. (Once a WIP item is finished, it graduates to “inventory” you can sell.)

What Does WIP Look Like vs. Raw Materials and Finished Goods

- Raw materials: Unopened or unused parts/components (e.g. fabric yardage, wood planks) not yet entered into production.

- Work-in-Process (WIP): Parts that have entered production. For instance, wood cut and partially sanded for a chair, or an unsealed candle in a curing rack. At this stage you can’t sell it yet. It includes all the costs so far (materials, labor, overhead).

- Finished goods: Fully assembled products that are complete and ready for sale (e.g. a completely built chair, or a boxed and labeled candle).

Put simply, WIP inventory represents the value of materials, labor, and overhead invested in products that are only partially complete. It’s a current asset on your balance sheet (since those products will soon become sales), but from a cash-flow perspective it’s money that’s temporarily “stuck” until the items finish production.

How to Calculate WIP Inventory (with an Example)

How to find work-in-process inventory

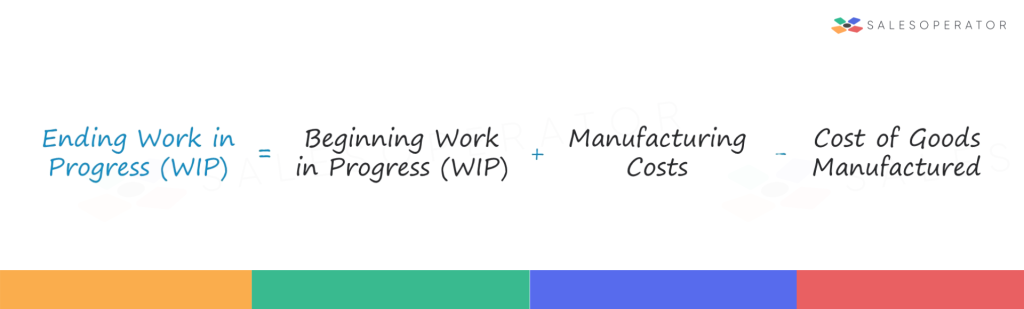

Calculating WIP helps you know exactly how much value is tied up in unfinished goods. The standard formula is:

Ending WIP Inventory = Beginning WIP + Manufacturing Costs – Cost of Goods Manufactured (COGM).

- Beginning WIP: The dollar value of partially finished goods at the start of the period.

- Manufacturing Costs: All production costs incurred during the period (raw materials used, direct labor applied, and manufacturing overhead).

- Cost of Goods Manufactured (COGM): The total cost of the goods that were finished during the period.

This formula simply means: add this period’s production costs to what was already in process, then subtract the cost of what you completed. The result is what’s still left as unfinished inventory at period end.

For example, imagine you start the year with $20,000 of WIP (partially built items). Over the year you spend $80,000 on new production (materials, labor, overhead). By year-end you’ve finished $75,000 worth of goods. Using the formula:

Ending WIP = ($20,000 + $80,000) – $75,000 = $25,000.

So you’d report $25,000 in WIP at year-end. In other words, $25K worth of product is still mid-production (and will become finished goods next period).

Here’s a step-by-step example calculation in a short form:

- Beginning WIP: $20,000 (from last year’s ending inventory).

- Add Production Costs: + $80,000 (materials, labor, overhead used this year).

- Subtract COGM: – $75,000 (value of goods you actually finished).

- Ending WIP: = $25,000.

Keeping track this way (ideally each month or quarter) gives you a clear picture of how much capital you have tied up in items on the production line.

Why Tracking WIP Matters for Your Ecommerce Business

For a small ecommerce or DTC brand that manufactures or assembles goods, understanding WIP is crucial. Here’s why WIP inventory deserves your attention:

- Cash Flow & Working Capital: Every dollar spent on a partially finished item is cash not in your bank. Excessive WIP ties up valuable capital. If you have too many unfinished units, you might find cash flow strained (cash that could otherwise fund marketing, pay suppliers, or invest in your next hot product). In other words, optimizing WIP (and avoiding huge piles of unfinished product) helps keep cash moving and improves liquidity.

- Storage & Carrying Costs: Unfinished products still occupy space. A warehouse full of half-built goods increases your carrying costs (warehouse rent, insurance, etc.) without generating revenue. If your WIP piles up, you’re literally burning resources on storing and insuring items that aren’t selling.

- Efficiency & Bottlenecks: High WIP levels often signal production problems. For example, if a lot of items are stuck halfway done, it may indicate a bottleneck (maybe a machine is slow or a key part is missing). Monitoring WIP helps you spot these hiccups. As Red Stag notes, tracking WIP “helps identify bottlenecks or quality issues in production”. Fixing bottlenecks means faster throughput and less waste of materials or time.

- Accurate Inventory and Forecasting: Knowing your WIP means you know exactly what inventory will be available soon. This improves your demand planning. If you don’t count work-in-process, you might under- or over-order raw materials. For instance, you might order more widgets thinking you need them, when actually you already have extra widgets in partially assembled orders. Accurate WIP tracking feeds into better reorder and production decisions.

- Customer Service (Prevent Stockouts): If you ignore WIP, you might misjudge how many finished items you’ll have. This can lead to stockouts or delays. Imagine you promise 100 units to a customer but forget that 20 of those units are still half-built. That order will ship late or need canceling. By tracking WIP, you always know how much production is still pending and can communicate realistic delivery dates.

- Financial Reporting and Funding: WIP is counted as a current asset on your balance sheet. Lenders and investors often look at inventory values (including WIP) when evaluating your business. Showing that you manage WIP inventory carefully can actually improve your financial statements.

In short, good WIP management keeps your production lean and responsive. It avoids unnecessary costs and ties your dollars up in actual sellable products rather than unfinished stock. As one logistics expert puts it, excess WIP management simply “leads to cash flow strain, increased storage costs, [and] risk of obsolescence”.

A Real-Life WIP Scenario

To make this concrete, let’s consider a small example. Imagine you run a handcrafted furniture business:

- Raw Materials: You have lumber, screws, and varnish in inventory waiting for production.

- Production: You’re building custom tables. Today, ten tabletops are cut and glued, fifteen sets of legs are being sanded, and workers are assembling five tables. All of these items are WIP: they have value (you paid for the wood and time) but they aren’t finished tables yet.

- Finished Goods: Once a table is fully assembled, sanded, and varnished, it becomes a finished good.

Suppose on December 1 you had 3 tables entirely finished (ready to ship), and $5,000 worth of materials in-process. By December 31 you spent $12,000 on labor and materials building more tables, and by month’s end you’ve completed $10,000 worth of tables. Using the WIP formula:

Ending WIP (Dec 31) = $5,000 + $12,000 – $10,000 = $7,000.

This means at year-end you still have $7,000 worth of unfinished tables (maybe 2 full tables apart from finishing). If you didn’t track WIP inventory and instead only tracked finished goods, you might think you only had $0 in stock (3 finished at start + $10k finished – $10k finished = 3 finished). You’d miss the $7k locked in unfinished tables. That could cause confusion in ordering wood or committing to new customer orders.

Even without a formal calculation, just thinking through the steps can be eye-opening. Many Etsy or DTC sellers (like custom apparel, handmade candles, electronics kits, etc.) have some WIP. For them, keeping a simple log – “We have 50 units half-assembled” – can prevent plenty of headaches.

The Dangers of Ignoring WIP

What happens if you gloss over WIP? Often, you’ll face:

- Stockouts and Delays: You might assume you have more finished products than you actually do. This causes late shipments or lost sales when demand spikes. As one inventory guide warns, a poor grip on inventory KPIs (like WIP) “risk[s] stockouts, overstocking, overselling, and ultimately unhappy customers”.

- Cash Flow Crunch: Not realizing how much capital is tied up in WIP can lead to a cash shortfall. You might suddenly find you can’t pay suppliers, even though a big chunk of cash is invested in unfinished goods on the shelf.

- Hidden Inefficiencies: Without tracking, bottlenecks stay hidden. You might waste labor on products that then just sit half-done. QuickBooks notes that unusually high WIP often signals inefficiencies or production delays, which “lead to increased holding costs and potential cash flow problems”.

- Inventory Inaccuracy: Your inventory counts become unreliable. This can wreck your forecasts and purchasing. Over time, it erodes trust in your data, so you’re back to scrambling on Excel or guesswork.

In short: if you ignore WIP inventory, you’re flying blind on a significant part of your inventory. That leads to surprises like stockouts, late shipments, and unexpected cash needs. The solution is simply to make WIP a regular part of your inventory review, just as you do with raw materials or finished stock.

Automating WIP Tracking with SalesOperator

Modern inventory tools can make managing WIP inventory much easier. For example, SalesOperator is a multi-channel commerce platform that provides integrated analytics and SKU-level visibility. Instead of juggling spreadsheets, SalesOperator automatically collects data from all your sales and production channels. It then generates dashboards and reports showing exactly where every SKU stands.

- Centralized Inventory Dashboard: All your channels (Shopify, Amazon, Etsy, etc.) feed into one view. You can see how many units of each product are in stock, on order, and in production (WIP).

- SKU-Level Insights: SalesOperator breaks down inventory by SKU. Want to know how many “Blue Candle, Large” are half-made vs ready? The platform shows you those counts in real time. This lets you spot if one SKU has a pile-up of WIP while another is running low.

- Integrated Analytics: With sales and production data combined, the software highlights trends and issues. For instance, if WIP for a product is growing faster than it’s selling, you’ll see it immediately. SalesOperator’s reports “help you assess how the whole range of your products is doing”, so you can prioritize which production lines to speed up.

- Alerts & Automation: You can set alerts for low finished stock or high WIP. For example, if WIP inventory for a best-seller crosses a threshold, the system can notify you to either increase production or investigate a bottleneck. This level of automation ensures you fix problems early (avoiding the very stockouts or cash issues we discussed).

The bottom line: instead of manually adding up numbers, SalesOperator’s dashboards give you a single source of truth. As the company puts it, they “collect all the essential information from different sales channels” and present it cleanly so “you understand your business better”. That means fewer surprises. You’ll always know if cash is tied up in partially-made goods, and you can adjust orders or production on the fly.

Take Control and Improve Your Operations

For a small ecommerce or DTC brand, implementing WIP tracking is a game-changer. By defining and calculating WIP inventory, you make invisible costs visible. You avoid nasty surprises like a key order delayed because you thought a product was ready, or running out of cash because too much was invested in half-finished units.

The good news is you don’t have to do this alone. Tools like SalesOperator (and even simple ERP/inventory apps) can automate the grunt work and keep you updated in real time. With a few minutes of setup, you’ll gain insights that save hours of frantic scrambling later.

In summary: know your WIP inventory, track it regularly, and use the right systems to manage it. That way, your business will flow more smoothly, your cash will be put to the best use, and you’ll deliver to customers on time. It’s a smart step toward running a leaner, more predictable operation – exactly what growing ecommerce businesses need.